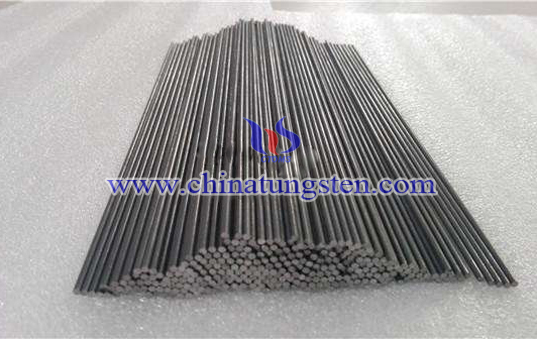

Round Tip Tungsten Needle

Round tip tungsten needle is round tungsten needle of slender structures, surface rich metallic. For the use of argon arc welding electrode. Argon arc welding technology at home and abroad is the development of a welding technology of the fastest, the most widely used. Especially manual argon tungsten arc welding, has become a necessary means in welding of various metal structure. When welding, tungsten electrode and the workpiece in the generated between the filler metal into the arc, from one side, under the action of the arc heat, filler metal and the workpiece are fused together to form a welding seam. In order to prevent the melting and burning of the electrode, welding current is not too large, therefore, tungsten argon arc welding is usually applied in welding of thin plate under 4mm, such as pipe butt joint, tube to tube sheet joint.

The tungsten needle mainly have two kinds of production process: a metal injection molding process, the two drawing forming process.

The basic process of the metal injection molding process is, first of all the solid powder and the organic binder uniform mixing, granulating after heating plasticized state, with injection molding machine injection mold cavity curing forming. Then by chemical or thermal decomposition method will be blank in the binder removal, finally get the final product by the Sintering Densification of tungsten needle.

Drawing forming process is that the metal raw material is heated to the plastic, after stretching to the desired diameter, finally after shearing and cooling.